Australia has more than 140,000 kilometres of water pipes, enough to go around the earth nearly four times. This infrastructure is mostly out of sight, out of mind – until a pipe breaks and we lose water or are inundated by it.

Then, the disruption of a major pipe failure can affect everyone from the utility that has to conduct urgent maintenance, the business and residential customers without water, through to commuters stuck in traffic as urgent repairs are made.

Longer term, the expense of pipe repair and renewal has the potential to impact all of us through higher bills. With water, preventing leaks and loss is also vital to drought resilience.

Ageing infrastructure

“The built world, just like human beings, gets older every day,” says Professor Fang Chen, Executive Director of the Data Science Institute at the University of Technology Sydney (UTS). Australia’s water pipes are now, on average, 80 years old.

Just like a human octogenarian, this infrastructure needs closer monitoring and ‘preventive medicine’ to keep it going strong, she says. With pipe replacement costing thousands of dollars a metre, and given budget constraints, “the only choice is smarter maintenance”.

Professor Chen and Associate Professor Yang Wang lead an award-winning team of scientists in the UTS Data Science Institute focused on data-driven solutions for industry. As well as water, the institute’s Smart Infrastructure team works with the owners of pipes delivering sewerage and gas services around the world.

Collaborating with more than 30 utilities in Australia and internationally, they’ve examined 1 million pipe failure records for 10 million pipes over the past decade.

Using advanced machine learning techniques and multiple sources of data, “we help owners understand their infrastructure’s performance, we help them to predict infrastructure failure, and we help them to reduce costs by carrying maintenance out in a more efficient way”, Associate Professor Wang says.

As a result, a much greater share of budget can go towards preventing disruption and improving the network as opposed to “reactive” maintenance which responds to leaks and ruptures once they happen.

This sort of impact earned the team an ‘Oscar’ for science in the form of the Australian Museum Eureka Prize for Excellence in Data Science in 2018.

What we’re finding is that our top 20 per cent predicts 80 per cent of the failures that are detected.

Distinguished Professor Fang Chen

Picking pipes

In one collaboration, Sydney Water, which serves 5 million customers, gave the UTS researchers access to 20 years of digital data so they could develop a pipe failure prediction tool to help the utility better target its maintenance and renewal budget. It’s a world-first pipe predictive model of this nature.

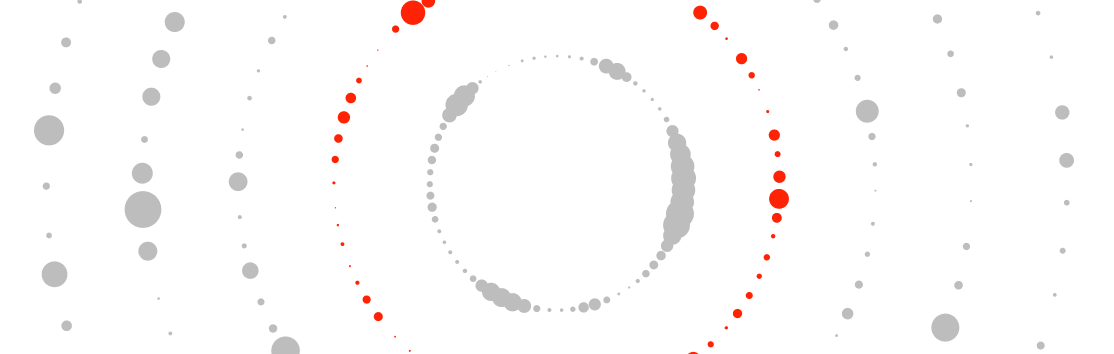

This sort of predictive tool for critical water mains can be used to better understand where and when pipe failure occurs. “With our prediction tool we can identify and visualise high-risk pipes on a map-based platform,” Prof Yang says.

The new failure prediction tool, combined with information from sensors developed by UTS robotics researchers, is being used to better target “intelligent” condition assessments, and repairs and renewals, to improve the performance of water assets.

The researchers’ interrogation of this data has identified more than 20 predictive factors drawn from four buckets of information:

- the attributes of pipes, such as when they were laid and what they’re made of.

- the environment in which they exist – whether they lie in a sandy or clay base, for instance.

- operational parameters such as the running pressure and presence of chemicals.

- incident or failure records showing what has happened in the past and why.

Researchers have been checking quarterly to see how the tool’s predictions measure up against the actual experience. “What we’re finding is that our top 20 per cent predicts 80 per cent of the failures that are detected,” Prof Chen says. Some 80 per cent of the predicted locations have been within 200 metres either way of an actual failure.

What’s next?

Looking ahead, this sort of prediction tool will help utilities select pipes for the application of cutting-edge technology such as acoustic sensors that monitor for vibrations caused by leaks. In turn, sensor technology will feedback more detailed information into predictive analytics.

UTS researchers are also extending their work into areas such as developing predictive tools to optimise water quality performance, develop disinfection strategies and fine-tune sewer chemical dosing.

Report/papers

B. Zhang, T. Guo, L. Zhang, P. Lin, Y. Wang, J. Zhou, and F. Chen, ‘Water Pipe Failure Prediction: A Machine Learning Approach Enhanced By Domain Knowledge’, In J. Zhou and F. Chen eds. Human and Machine Learning: Visible, Explainable, Trustworthy and Transparent, Chapter 18, pages 363-383, Springer, 2018.

Liang, B., Weeraddana, D., Li, Z., Lu, S., Fan, X., Wang Y., Chen F., … and Hayward M. (2018). Pipeline Failure Data Analytics and Prediction. Ozwater 2018.

Lin, P., Zhang, B., Wang, Y., Li, Z., Li, B., Wang, Y., and Chen, F. (2015, October). Data driven water pipe failure prediction: A bayesian nonparametric approach. In Proceedings of the 24th ACM International on Conference on Information and Knowledge Management (pp. 193-202).

Li, Z., Zhang, B., Wang, Y., Chen, F., Taib, R., Whiffin, V., and Wang, Y. (2014). Water pipe condition assessment: a hierarchical beta process approach for sparse incident data. Machine learning, 95(1), 11-26.

Faculty

- Faculty of Engineering and Information Technology

- Data Science Institute

Funded by

- Sydney Water

- Western Water

- UnityWater

- Queensland Urban Utilities

- SA Water

- UK Water Industry Research